The History of the Barcode

8th August, 2017

It’s hard to imagine a world without barcodes. Before their existence, product codes and information would be inputted by hand, resulting in long queues in stores and laborious stock checking; not to mention all the errors caused by manually inputting data.

Nowadays, companies can significantly improve production with highly reliable barcoding equipment. While George J Laurer created the standardised barcode we are all familiar with today, its predecessor, a circular bullseye design, was originally created by Norman Joseph Woodland and Bernard Silver in the late 1940s. We take a look at the history of the barcode, the pros and cons of using a barcode, as well as looking at the future of barcodes and the challenges faced today.

Barcode History

The idea of a scannable code used to identify products was originally intended for the food and drink industry. The story goes that Woodland was sitting on a beach in Miami one day, thinking about how morse code can transmit messages simply using dots and dashes, as he drew in the sand with his finger. This was his ‘eureka’ moment – instead of dots and dashes, wide and narrow lines could be used to convey a message. He then swept his fingers round in a circle, giving us the original bullseye design. However, the equipment used to produce the circular codes was too expensive and unreliable – codes were often smeared in the process, and any defects made the code unreadable.

Several different methods were pitched, however, it was George J Laurer who went against the grain and created a rectangular code when he realised that the circular design could not match the specifications – 1.5 square inches in size and readable in any orientation. To store the amount of data required, the circular codes would be much too large to fit the specification given. To solve the issue of scanner readability, Laurer proposed adding a mirror to the scanner to make the single line into an ‘X’ shape, allowing the code to be read in any orientation; and included guide bars and different codes on each side of the barcode for each individual number – this lets the computer know which way it was reading the code and allowed it to be reversed.

In 1974, almost three decades after the original idea was proposed, the first item to be scanned in-store was a pack of Wrigley’s gum, chosen to prove that such a small item could be barcoded and identified correctly.

Composition of barcodes

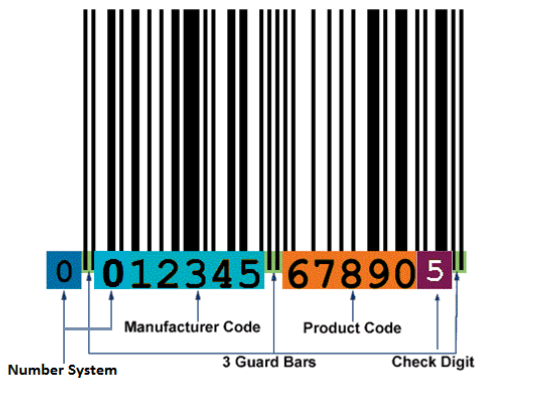

Barcodes are composed of 95 columns of equal width. The beginning and end of the code are marked by longer ‘guard bars’, and the columns are split in half by a middle guard bar.

The left side indicates category, manufacturer and the manufacturing company’s location, The right side identifies the product itself. The final digit is used as an error checker, to make sure the barcode has been read correctly.

Pros and Cons of Barcodes

Barcodes are not inherently good or bad, but depending on the usage and the business or organisation, barcodes may present the following pros and cons;

Pros

Faster Data Entry and Inventory control

Barcodes allow for faster and more accurate inventory control, allowing databases to be updated instantly.

Improved Error Reduction

By using barcodes, errors in data input and handling are greatly reduced – one medical study shows barcodes provide a significant reduction in administration errors when compared to human data entry.

Less paperwork

No explanation needed. Who wouldn’t want less paperwork?

Cons

Initial Setup can be costly

Equipment costs money. Barcoding may not be suitable for every business, especially smaller businesses. The ROI needs to be carefully calculated and considered before any decisions are made.

Equipment takes time to get used to

As with the implementation of any new system, it can take some time to get accustomed to the equipment and systems put in place for additional training. As with financial investment, the investment of time needed to transition and get used to the new system should not be overlooked.

The Future of Barcodes

As well as the standard barcodes we are used to seeing on consumer products, there several other types of barcode that have different uses, such as packing and shipping and pharmaceuticals.

Since the introduction of one-dimensional (linear) barcodes, two-dimensional codes have emerged – among the most recognisable are QR codes.

Invented in 1994, QR codes have no central authority dictating their composition or usage, unlike the GS1 having authority over UPC and EAN barcodes. This has led to them being misused by advertisers, leaving some consumers with a sour taste in the mouth.

2D codes can store much more data than their 1D counterparts, including storing URLs, contact details, or entire passages of text – this paragraph is represented in the QR code on the right. As shown here, images and colour can be added to make the code stand out.

RFID Tags

Though Radio-Frequency Identification tags (RFID tags) are not barcodes, they serve a similar purpose and are considered by some to be the next logical step in automated identification. Some of the main advantages are that multiple items can be scanned at once and that they can be updated easily.

However, there are still several drawbacks: RFID tags and systems may suffer from signal collision and are more expensive and more complicated to implement than barcodes, which can easily be printed on most materials in-house.

Since its creation, the barcode has spread far away from its origins in the grocery industry. Nowadays, not only do barcodes allow for faster checkout lines in stores across the globe, they serve more purposes than the inventors could have ever imagined: they also allow faster and more efficient data collection and stock checking, monitoring of prescriptions and endangered animals, to name but a few.

Interactive Coding Equipment provides barcode solutions for products and packaging in the UK with a range of technologies including Thermal Transfer, Thermal inkjet, Print and Apply Labeller and Case Coding machines.

Related

FREE DOWNLOADABLE ICE GUIDE PROVIDES INSIGHT INTO BARCODES

More Resources